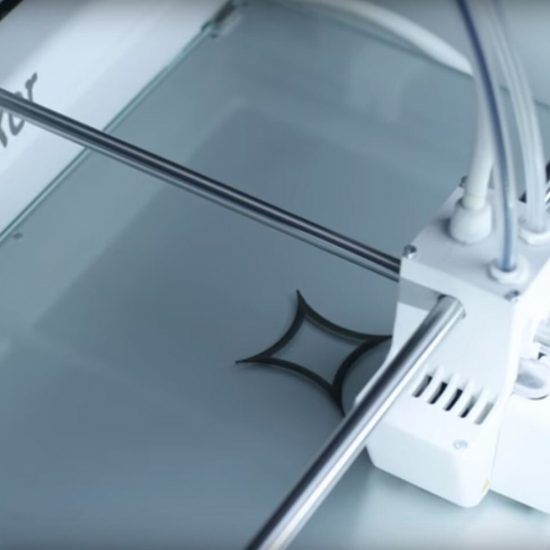

3D Printing Machine – Ultimaker S5

To enhance what we are able to offer our customers we have added to our prototyping options in-house with the purchase of a brand-new 3D Printing machine, an Ultimaker S5. This allows us to fully evaluate part design and prototypes to meet customer demands. Printing 3D parts can also be very useful when carrying out DFMEA’s.

3D Printing allows low cost and time efficient prototyping. Various materials can be printed to suit the material specified for the production components to give the best possible match. Choice of materials includes:

PLA, Nylon, ABS, PC, CPE, Nylon, PP, combined with PVA support material up to size:

-Width (X) 330mm

-Depth (Y) 240mm

-Height (Z) 300mm